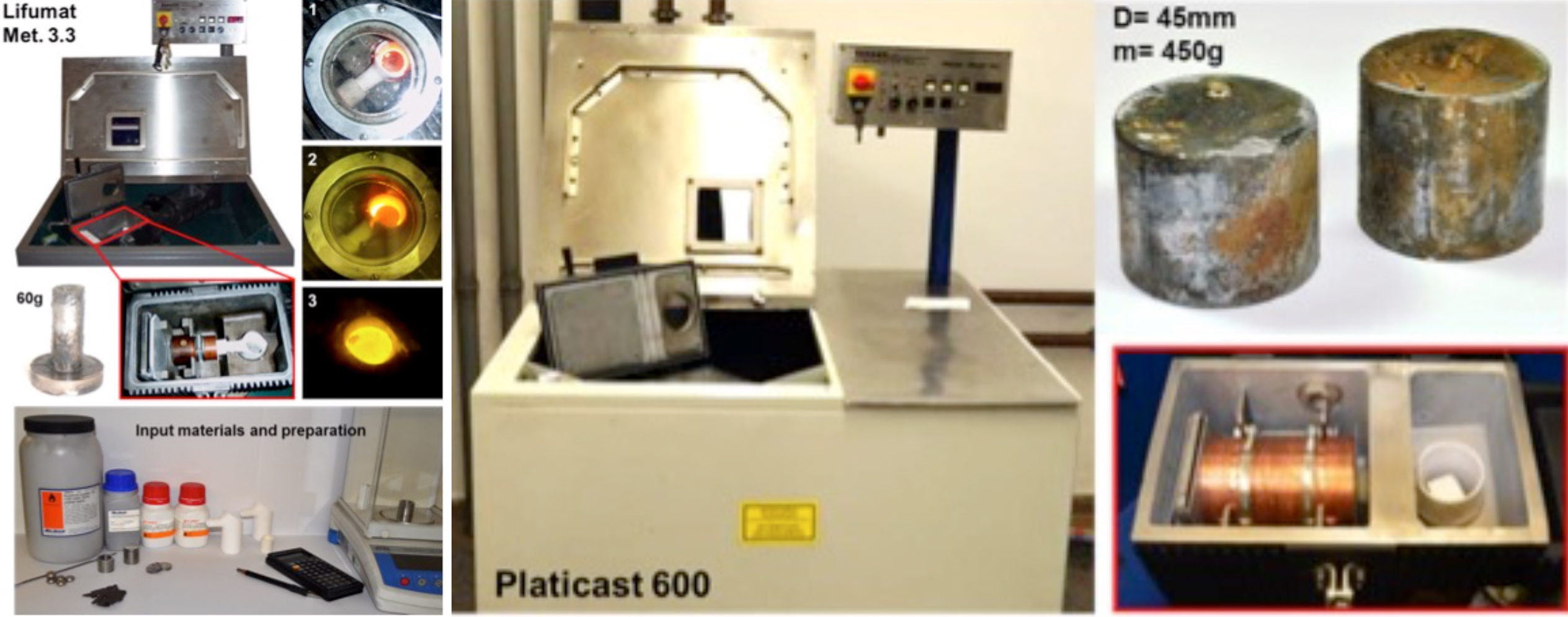

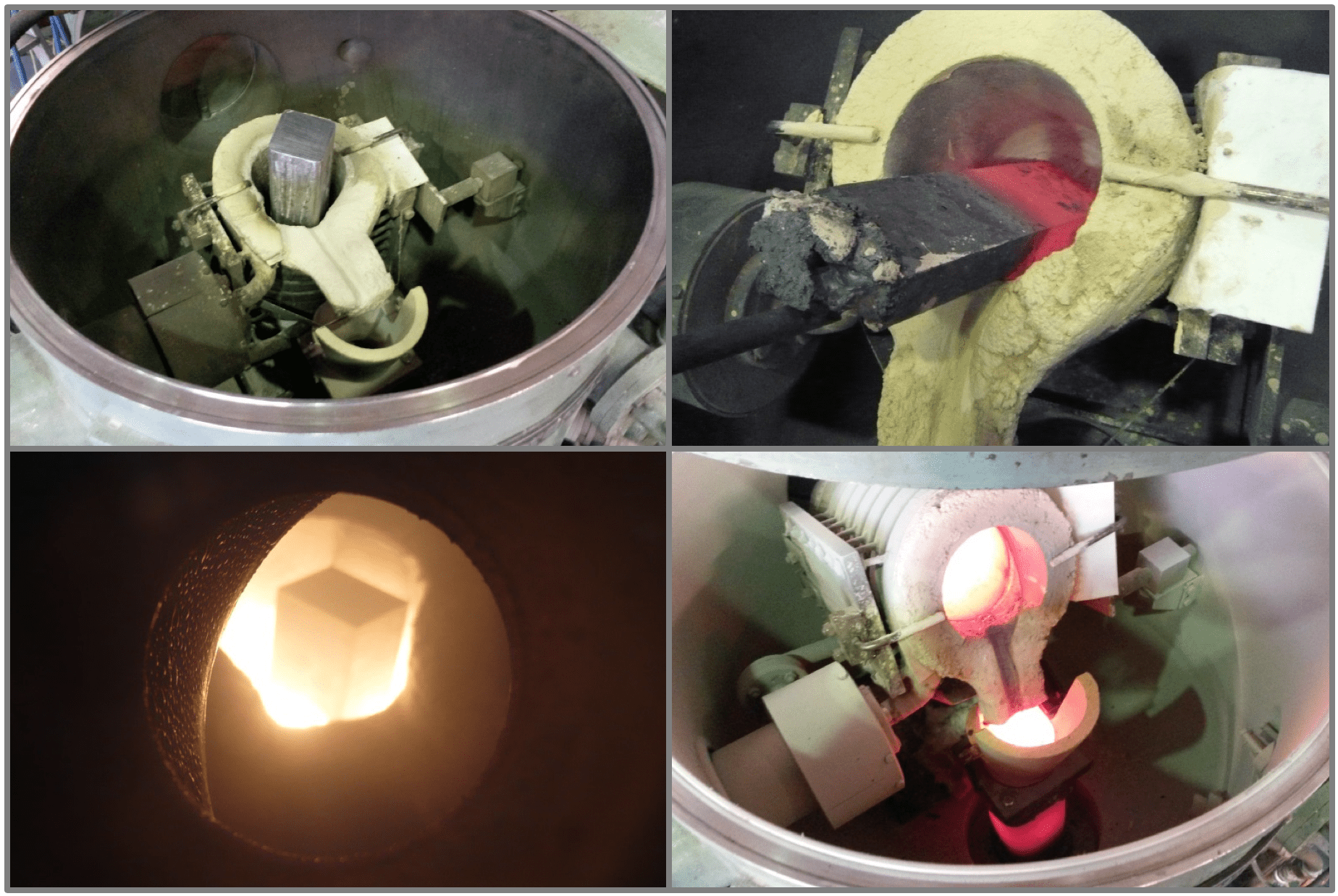

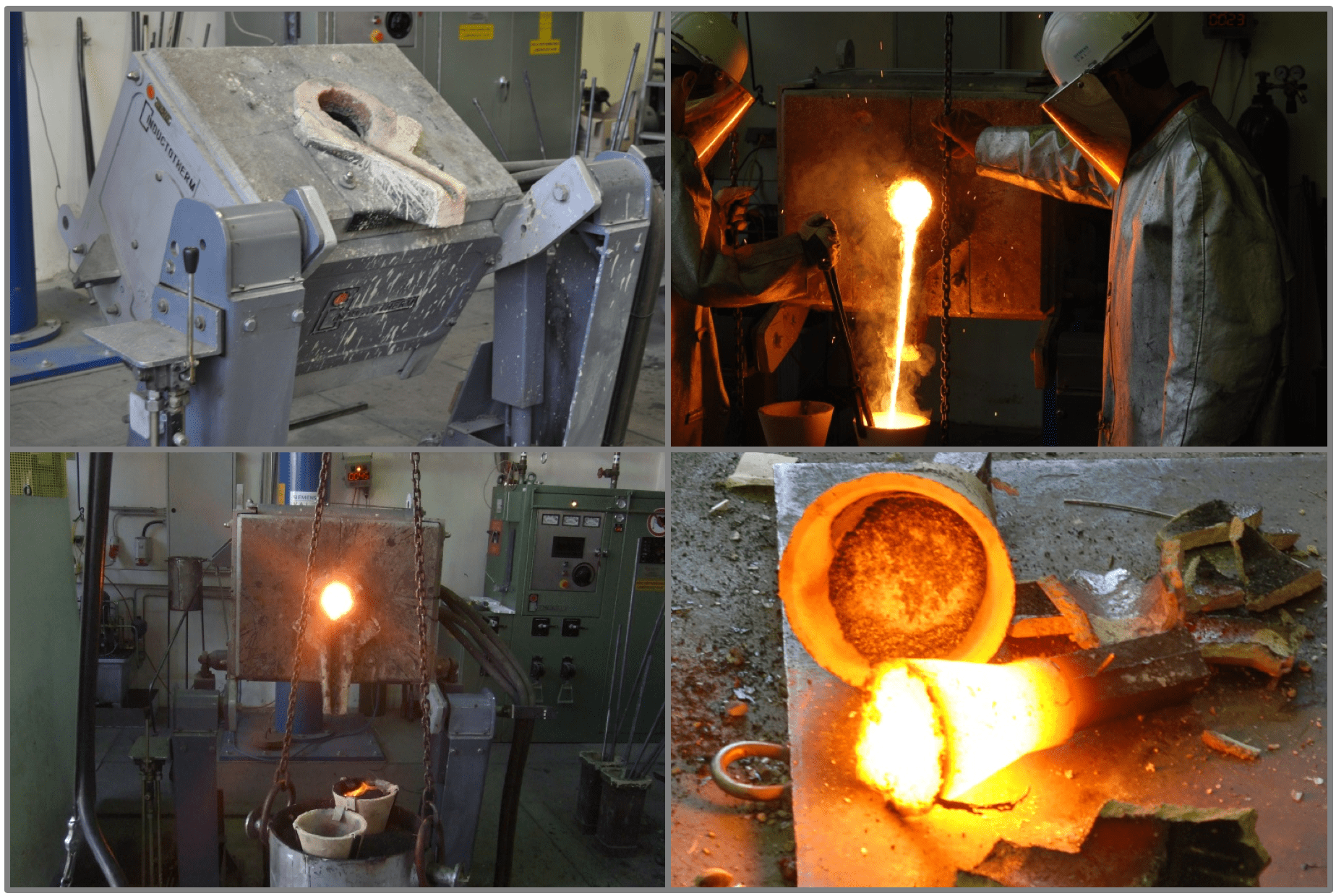

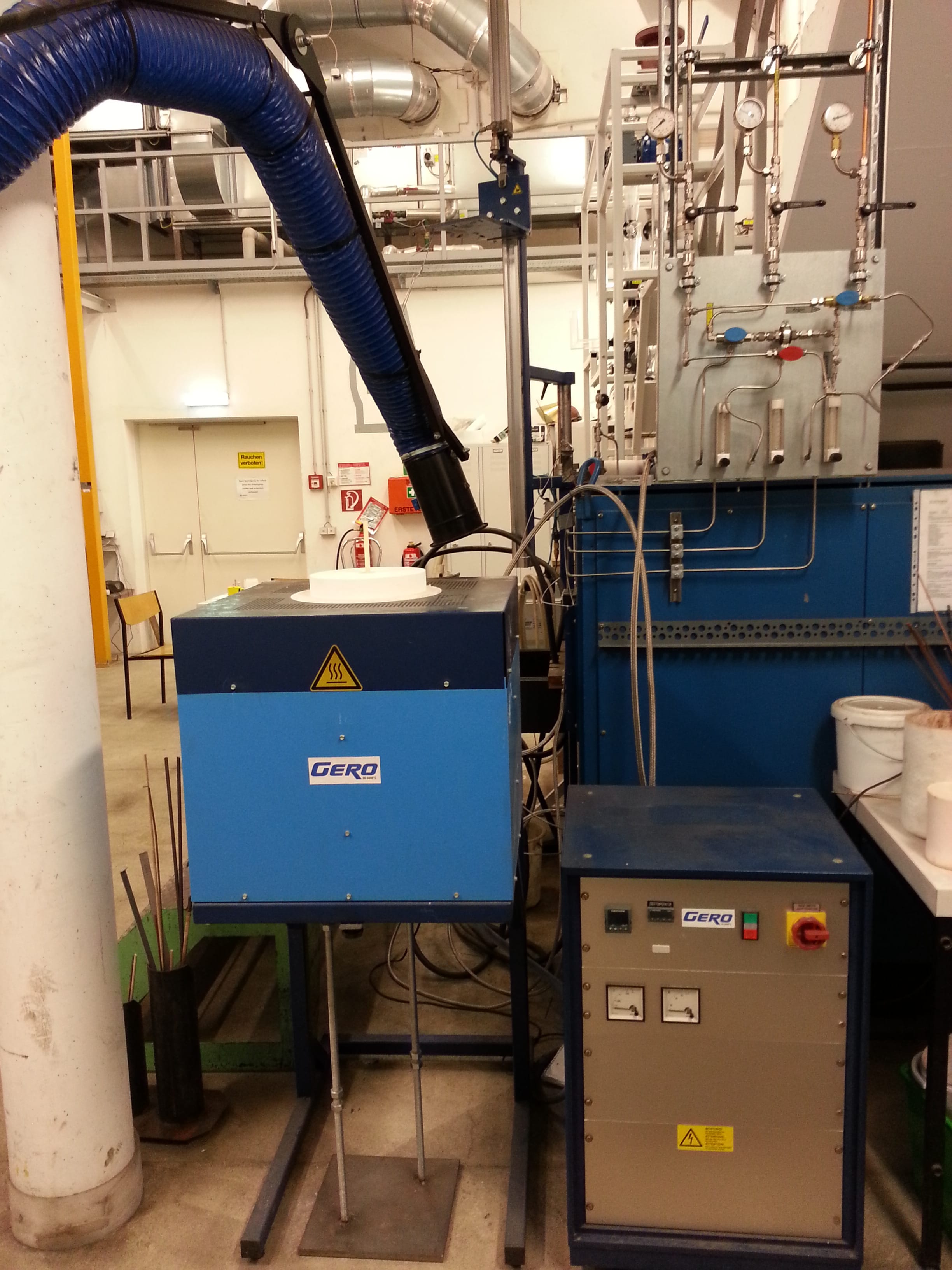

High frequency remelting furnace (HFR)

The High-frequency remelting (HFR) and spin-casting machine allows the rapid production of laboratory alloys by induction melting under argon protective atmosphere. The turbulent flow from the induction provides an excellent mixing of the melt and the closed melting chamber prevents oxidation. The subsequent (optional) centrifugal spin-casting into a copper mould supports also the homogenization [...]