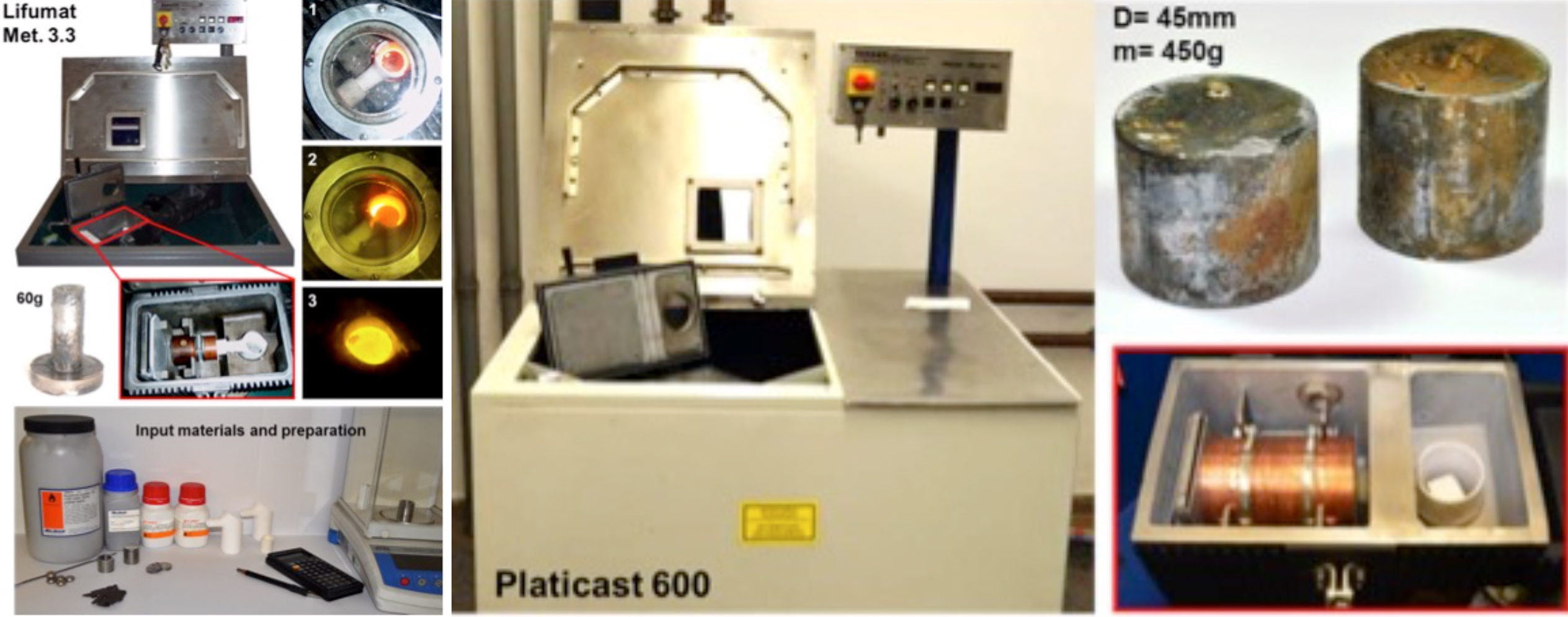

The High-frequency remelting (HFR) and spin-casting machine allows the rapid production of laboratory alloys by induction melting under argon protective atmosphere. The turbulent flow from the induction provides an excellent mixing of the melt and the closed melting chamber prevents oxidation. The subsequent (optional) centrifugal spin-casting into a copper mould supports also the homogenization of the melt and promotes a very fast solidification. Two HFR’s from Linn High Term GmbH are available, a small “Lifumat Met. 3.3” and a big “Platicast 600”. With this plants, new laboratory alloys can be produced in a save, quick and cost-efficient way (e.g. for creating phase diagrams by DSC measurements)

Advantages and principle of the high-frequency remelting and spin-casting machines:

- rapid production of laboratory alloys

- sample size (60g or 450g)

- short test duration and rapid solidification

- possibility of centrifugal spin-casting into a copper mold (dense and homogeneous samples)

- use of ceramic (e.g. high purity alumina) crucible

- slag free melting

- use of high-purity alloying elements (laboratory chemicals)

- closed, inert melting chamber (argon purge)

- achieving of very high melting temperatures (melting of titanium and platinum).

Contact:

Peter Presoly

Dipl.-Ing. Dr.mont.Post Doc - Thermal Analysis and Thermodynamics