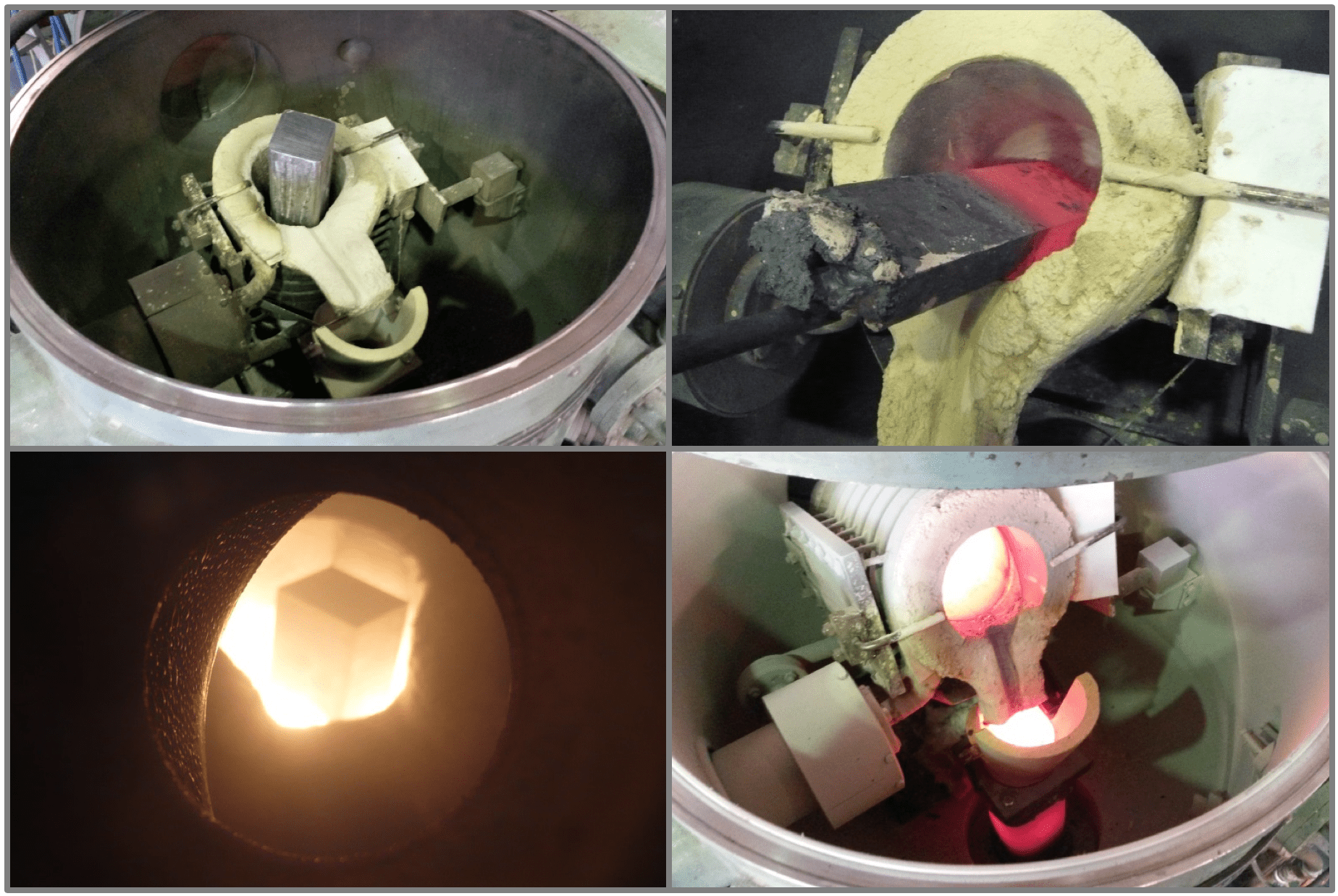

The Vacuum-Induction-Furnace is used for when high gas purity is requested. The chamber is vacuumed and further flooded with inert gas e.g. Argon 5.0. The raw materials consist of pure iron or remelted steels. Analytical measurements of the current composition allow the adjustment of the alloying element contents very accurate. Thus it is able to produce numerous steel grades or to vary the content of significant alloying elements.

Technical Specifications:

- max. temperature melt: 1650°C

- lining: ~90% MgO, ~8%Al2O3, ~2% CaO

- max. capacity: 20 kg

- ingot size: 14 kg

- casting process: tilting of crucible

Contact: