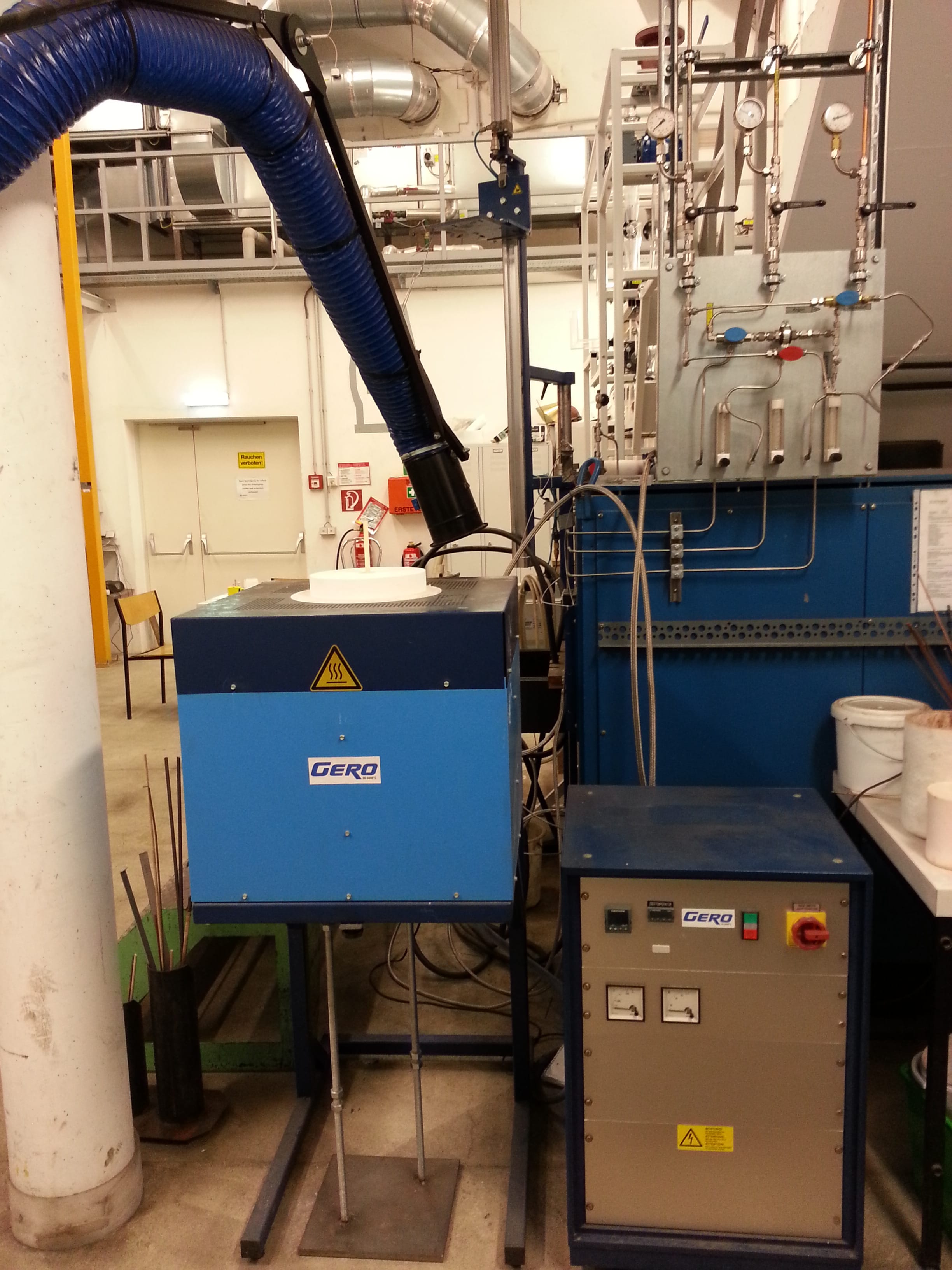

The GERO® High temperature vertical tube furnace HTR-V100-250/17 is used to observe the dissolution properties of slag formers and steel scrap in liquid slag and metallic liquids, respectively. Further, the refining of liquid slag is possible. The maximum temperatures are 1650 °C. The heating is carried out through molybdenum disilicide (MoSi2) heating elements with a heating rate up to 350 K/h. The investigated sample is axial transported through a pneumatic transportation unit which allows to insert the cold sample into the heated melt. The transport unit is rotatable in design, allowing rotational speeds up to 100 rpm for dynamic processes. The open furnace chamber allows experimental investigations under oxidizing atmosphere. The adjustment of oxidation process is possible to realize. With special equipment also the refining and reduction of slurries, dusts and slags is possible.

Further possibilities for usage: annealing, carbonisation, crystal growth, debinding, degassing, drying, glowing, hardening, pyrolysis, sintering, sublimation, synthesis, tempering

Principles and advantages of HTRV with modified gas atmosphere:

- sample holder which allows a movement into z-axis and rotation of sample

- rotational speed of the sample up to 100 rpm

- oxidizing gas atmosphere

- maximum crucible diameter 120 mm with a height of 80 mm

- submerging of cold samples into hot liquids

- heating rates up to 300K/h

Contact:

Bernd Taferner

Dipl.-Ing.PhD-candidate - Primary Metallurgy and Metallurgical Processes