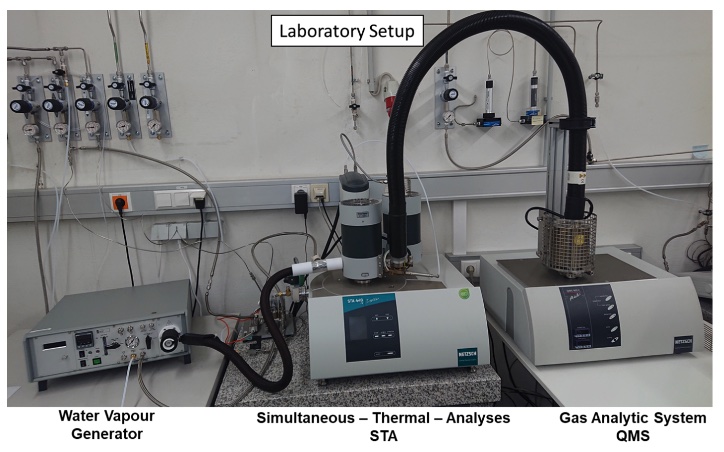

Simultaneous-Thermal-Analysis

Oxidation processes are almost unavoidable in the production and further processing of steel. Therefore, a better understanding of its mechanisms is crucial. Simulating selected process steps, like casting, heat treatment or hot rolling, by simultaneous-thermal-analysis (STA-DTA/TG measurements) improve the understanding of the influence of process parameters and steel composition on the formation of surface [...]