Increasing requirements on the properties of steel are challenging steel plant operators. Controlled cooling, as a part of most metallurgical processes, takes an important role in fulfilling these requirements. Optimal cooling strategies help to adjust mechanical properties and to minimize the formation or promotion of surface defects. But not only the steel quality is improved; a sustainable use of cooling water and air also helps to reduce the costs and the environmental impact of steel production.

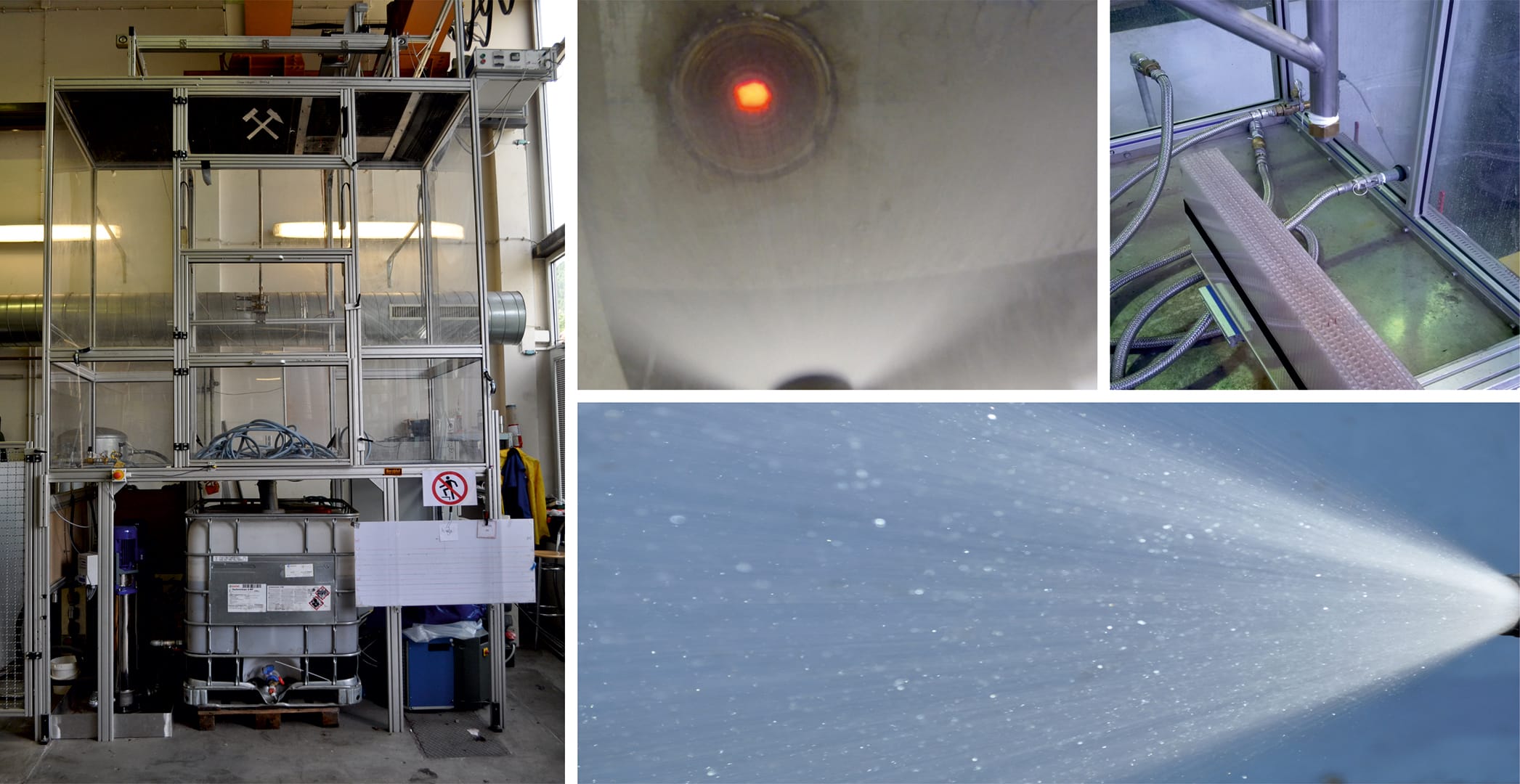

The Nozzle Measuring Stand at the Chair of Ferrous Metallurgy is used to investigate the cooling characteristic of nozzles at varying operation parameters. The gained data can be used in simulation models, like for the solidification modelling of the continuous casting process.

Following parameters can be adjusted to investigate their influence on cooling intensity:

- Water flow rate V(H2O)/ water pressure p(H2O)

- Air flow rate V(AIR)/ air pressure p(AIR)

- Sample velocity v (<6 m/min)

- Surface start temperature TStart(<1200 °C)

- Distance nozzle – surface Nz

- In case of two nozzles: Distance nozzle – nozzle Nx

Contact: