Research Area Thermodynamic Modeling and Metallurgy of Casting Processes

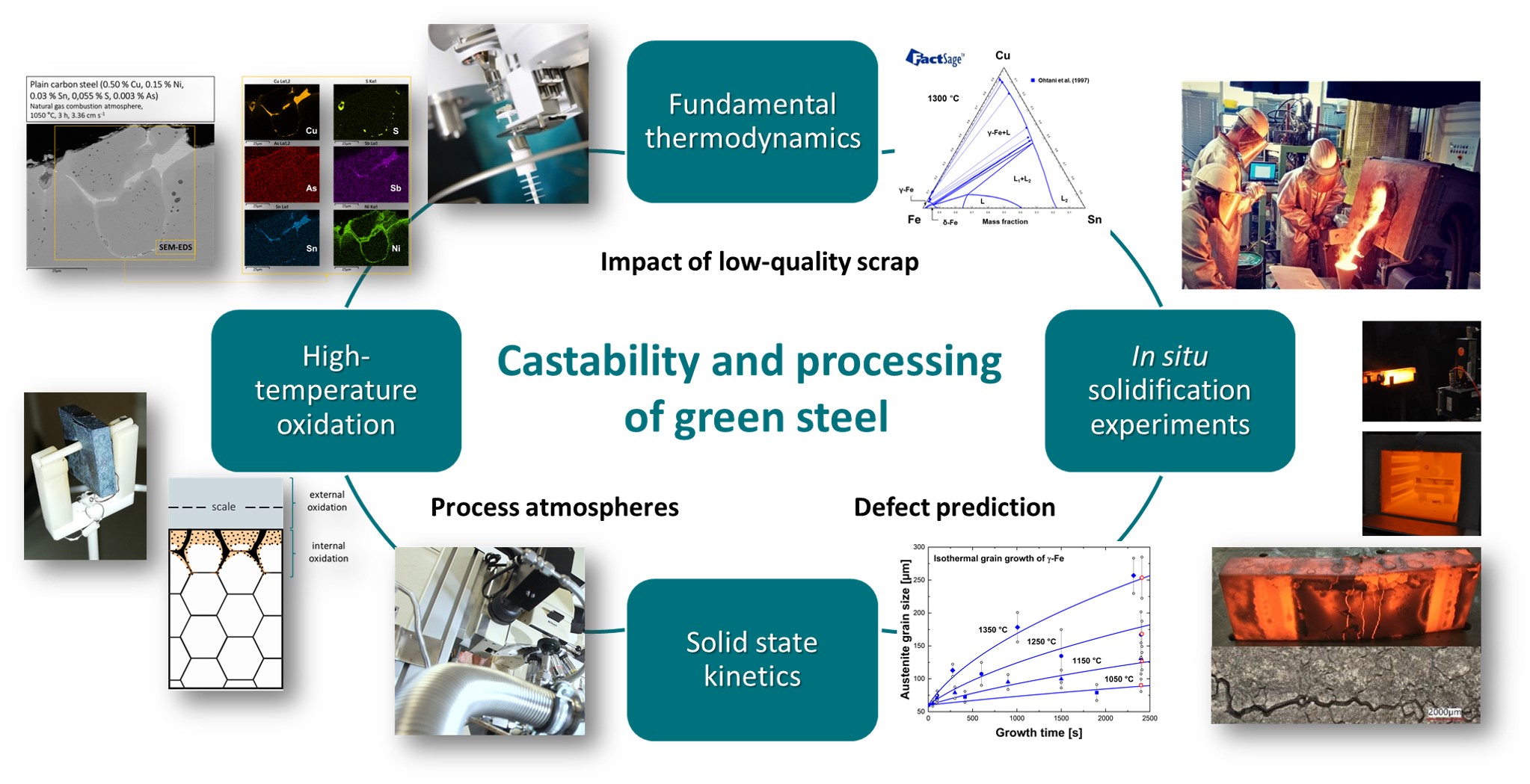

The research focus of our working group is broadly diversified and includes work on thermodynamic data and databases for steel and slag systems and the application of ChemApp-Python for thermodynamic modeling of steel production and processing. An example is the development of the “I-Clean” software for cleanness prediction in ladle treatment within a K1-MET project.

The prediction of the product quality of steel, based on data-based approaches, new sensor technology, phenomenological approaches, and globally unique experiments combined in hybrid models, has been a key topic for two decades. An important part of these activities is the classical solidification simulation (m²CAST), taking into account non-equilibrium states and phase transformation kinetics and the possibility of measuring heat transfer in a nozzle measuring stand, which is another focal point.

In recent years, the developed methods have been increasingly used to investigate the influence of tramp elements and residuals on casting and rolling processes. A particular focus here is research on the Endless Strip Casting Process (Arvedi ESP). Today, a well-equipped setup for investigating high-temperature surface oxidation on a laboratory scale (Netzsch STA, aSteam water vapor generator, mass spectrometer) is available to investigate internal and external oxidation phenomena and decarburization for casting and rolling processes. This part of our work is a valuable contribution to decarbonizing steel production processes.

The working group cooperates with Austrian companies (voestalpine, Primetals Technologies, RHI Magnesita) and notable companies in Germany and Asia.

In recent decades, numerous PhDs and master’s theses have been successfully completed. Research-based teaching is a classic extension of our research activities.

We are an active part of a worldwide scientific network and are open to collaborations.

Contact: Ao.Univ.-Prof. Dipl.-Ing. Dr.mont. Christian Bernhard, Dipl.-Ing. Dr.mont. Peter Presoly, Dipl.-Ing. Dr.mont. Michael Bernhard