Research Area Inclusion and Secondary Metallurgy

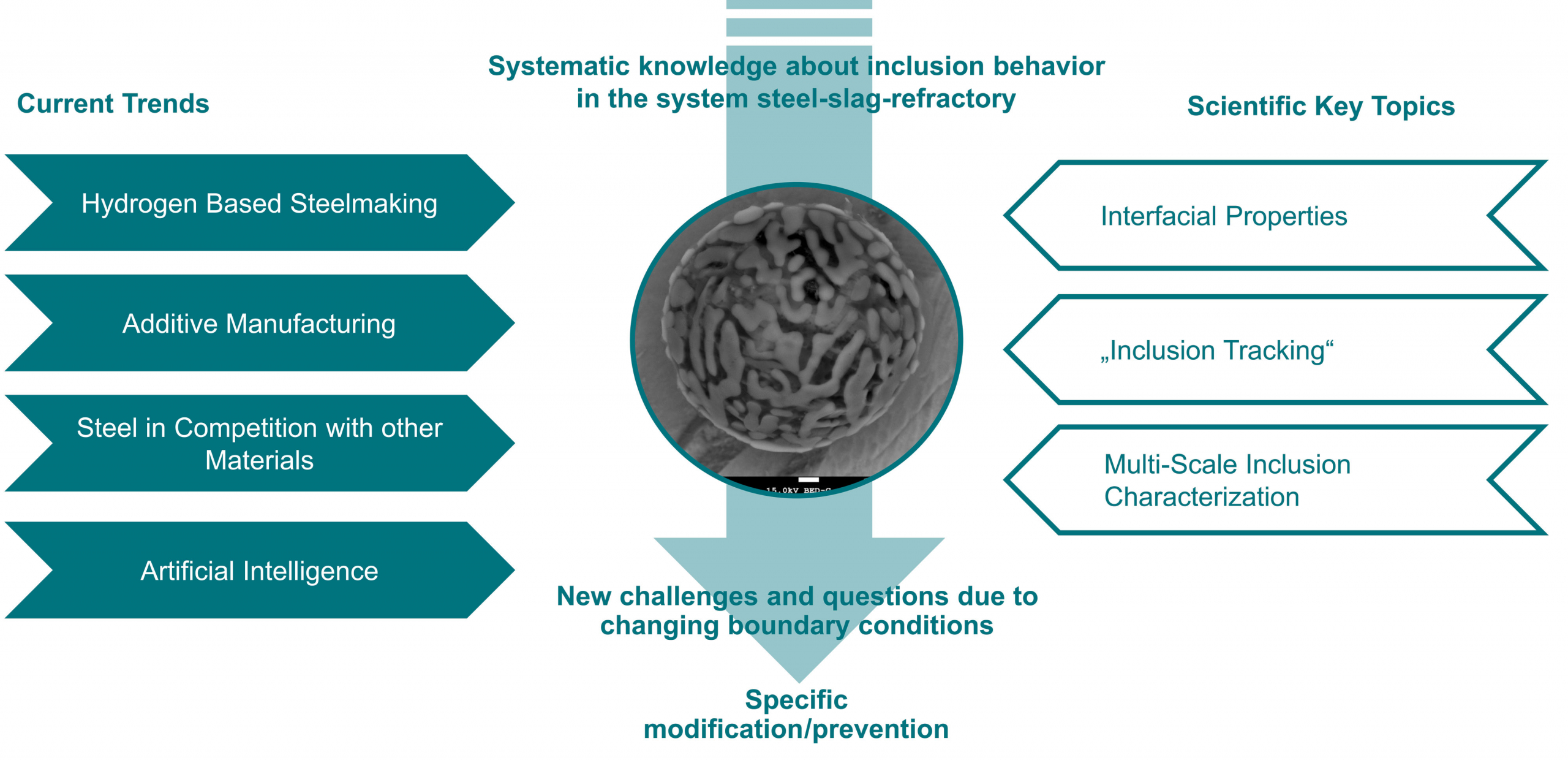

The final steel quality is in many cases inextricably linked with the steel cleanness. Regardless of the steel composition and its application, there are cleanness-sensitive steels in all areas – from ultra-low carbon steels for automotive applications, electrical steels, spring steels to high alloyed steels produced via powder metallurgy. Also, the current transformation of steelmaking to reduce the CO2 footprint influences the necessary secondary metallurgical treatments to maintain the desired product properties. Under the overarching goal of sustainable steel production in the spirit of the circular economy, the Inclusion Metallurgy research field enhances the understanding of steel cleanness related topics from a fundamental point of view as well as conducts application-oriented research with industry partners and a global scientific network. The primary aim is to study the relation and interaction between micro-, meso- and macro-cleanness in steel by using a multidisciplinary approach. This considers establishing a bridge from inclusion formation over their modification and evolution in the system steel-slag-refractory to their final impact on material properties for specific applications and different processes.

Current research topics are:

- Influence of tramp elements and alkali metals: Increased content of tramp elements (Copper, Tin, …) in steel due to the scrap-based production route necessitates to study their interaction and impact on inclusions and interfacial properties.

Adding alkali metals oxides such as Lithium oxide, Sodium oxide, or Potassium oxide to the slags used in secondary metallurgy can enhance the dissolution of non-metallic inclusions and, therefore, increase the level of steel cleanness. - Inclusion analytics: Enhancing inclusion characterization and deepening the understanding regarding inclusion morphology using machine learning.

Developing AI-assisted inclusion analytics linked with process data from steelmaking. - Inclusion tracking: Establishing of active (direct addition of rare earth elements) and passive tracing (rare earth element and isotopic fingerprint) techniques for a systematic tracking of inclusions, especially for the meso-size range.

- Physics-based modelling: Thermodynamic and kinetic modelling of inclusion behavior combined with experimental verification on laboratory scale.

- Clogging: Understanding the phenomenon considering the role of non-metallic inclusions and interfacial properties in connection with numerical simulations.

- Quality-related processing of high-alloyed steels

Since 2021 the Christian Doppler Laboratory for Inclusion Metallurgy in Advanced Steelmaking (https://cdl-imas.at/) is established and significantly contributes and conducts the described research.

Contact: Univ.-Prof. Dipl.-Ing. Dr.mont. Susanne Michelic

We are always looking for motivated and interested students and cooperation partners to enlarge our network!