The Submerged-Split-Chill-Tensile (SSCT) machine was originally developed at EPF Lausanne in 1985 and is used for in-situ characterization of strength and hot tearing sensitivity of steel during solidification. An additional in-house simulation software enables the coupled numerical calculation of solidification progress and hot tearing formation in the experiment.

Principles and advantages of SSCT-machine:

The cylindrical test body is made of construction steel and consists of an upper and a lower part. Two thermocouples of type k are placed inside the test body to measure the temperature and to determine the heatflux during the experiment by inverse method.

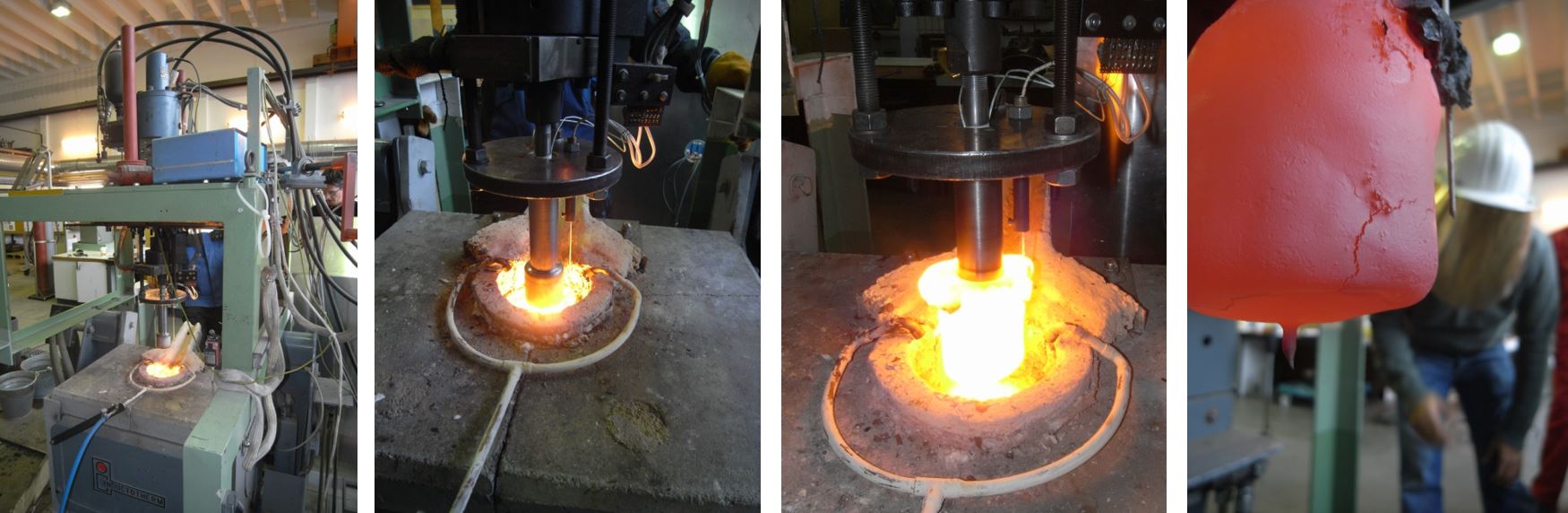

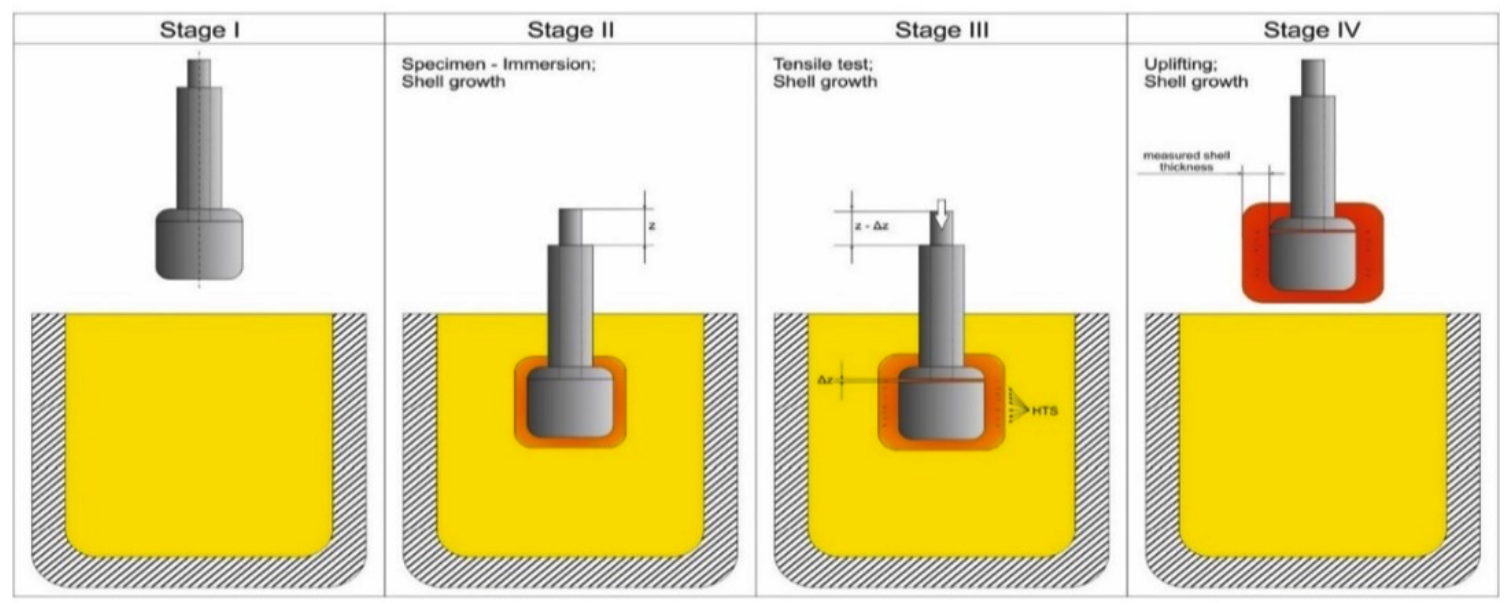

In general, the SSCT-test procedure can be divided into four stages:

- The test body is placed above the liquid steel at stage I. The melt is prepared in an induction furnace with a capacity of 25 kg.

- During stage II the test body is submerged into the liquid steel, shell growth proceeds for a specified period of time.

- At stage III the actual tensile test starts: The lower part moves down with a given velocity (corresponds to a given strain rate) and a predefined total strain is induced into the solidifying shell. If the strain exceeds critical values, hot tear segregations (HTS) will be formed during the experiment.

- After the tensile test has finished the test body is lifted out of the melt during stage IV. After the specimen is cooled down to room temperature the solidified shell is cut into pieces for the further metallographic investigations.

Contact:

Michael Bernhard

Dipl.-Ing. Dr.mont.Thermodynamics of Steels