The Hydrogen-Carbon Centre at Montanuniversität Leoben was inaugurated in October of this year. The Chair of Ferrous Metallurgy is also involved with two research facilities: a multi-cathode furnace and an arc-based plasma pyrolysis system.

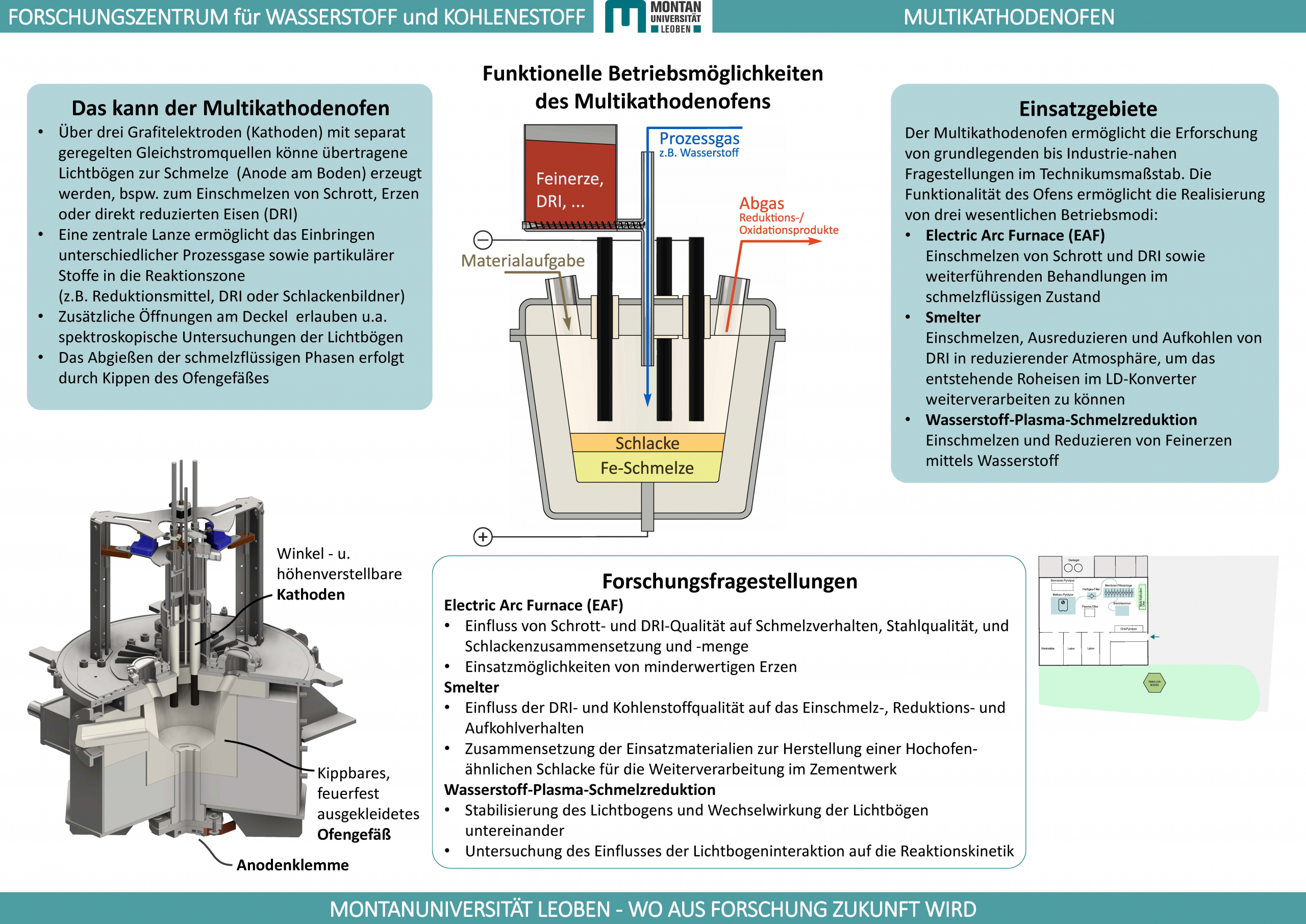

The multi-cathode furnace allows us to conduct research into fundamental to industrial-scale issues on a pilot plant scale. The furnace`s functionality allows for three main operational modes to be carried out:

- Electric Arc Furnace

Melting of scrap and direct reduced iron (DRI) as well as further treatments in the molten state

- Smelter

Melting, reducing and carburizing of DRI in a reducing atmosphere in order to process the resulting pig iron further in a basic oxygen converter

- Hydrogen plasma smelting reduction

Smelting and reduction of fine ores using hydrogen

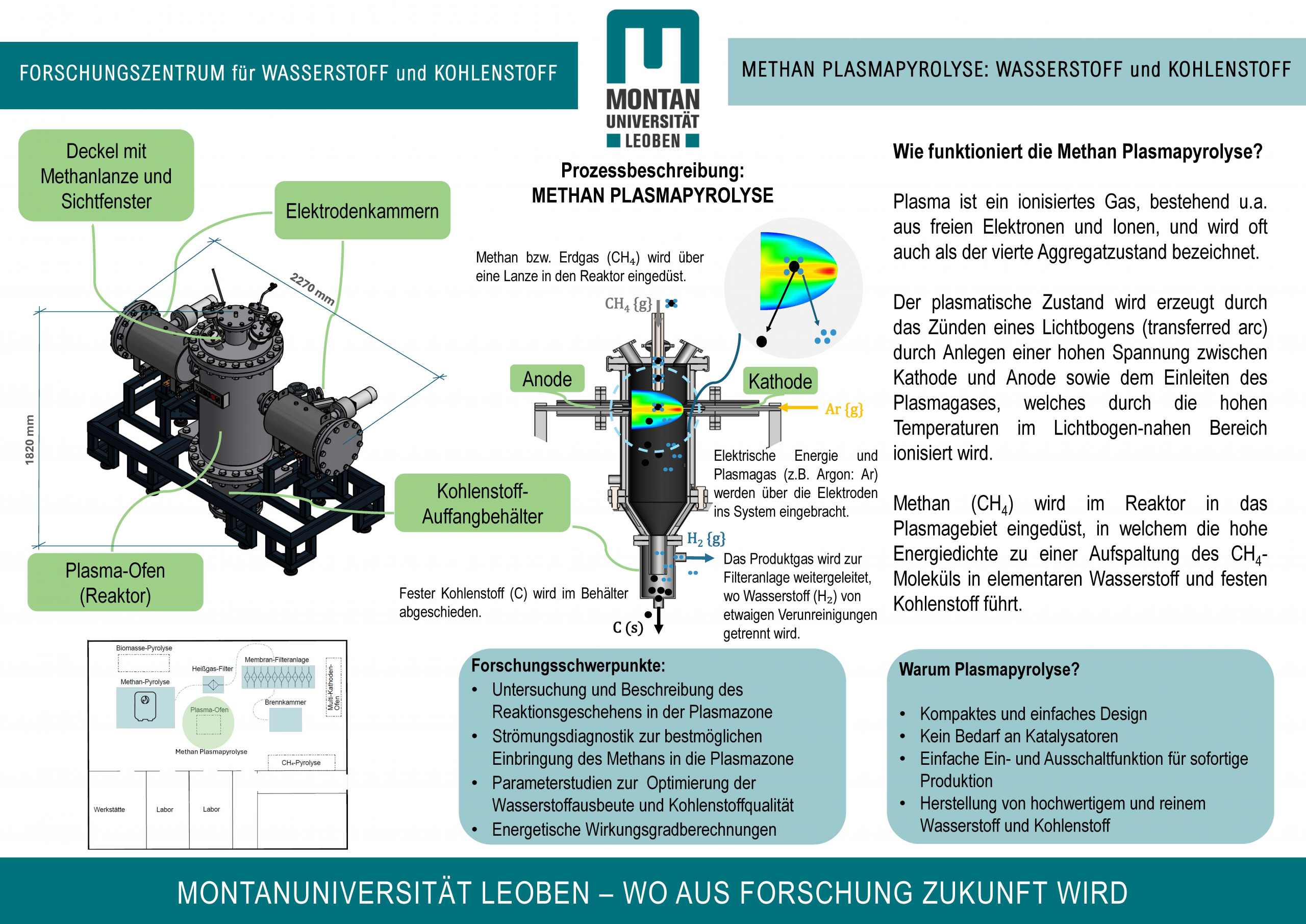

In the plasma zone of the arc of the pyrolysis facility, the high energy density is used to split the methane molecule into elementary hydrogen and solid carbon. The pilot plant will be used to focus on the following research areas:

- Investigation and description of the reaction process in the plasma zone

- Flow diagnostics to optimize the methane injection into the plasma zone

- Parameter studies to optimize the hydrogen yield and carbon quality

- Calculations on energy efficiency

We are pleased to announce that both test facilities are currently being finalized and are scheduled to go into operation in the coming months.