Cost-efficient, flexible and simple production of single parts and small batches

The basic features of additive manufacturing, also known as layer manufacturing or 3D printing, have been around for about 30 years. This process only became known to the general public after various patents expired, which opened up the free market for 3D printing.

In contrast to conventional production, 3D printing is based on an additive process. The product is built up in layers instead of being milled from a block or casted. The first advantage is that there is virtually no loss of material. The design data from 3D CAD software (e.g. Solid Edge, NX, etc.) forms the basis of every 3D object.

3D printing is the future in the manufacturing industry

We find the application areas of 3D printing in all industries. Some benefit particularly from the advantages of this printing process, e.g. due to the low weight of the parts produced or the possibility of quickly implementing special designs on customer request.

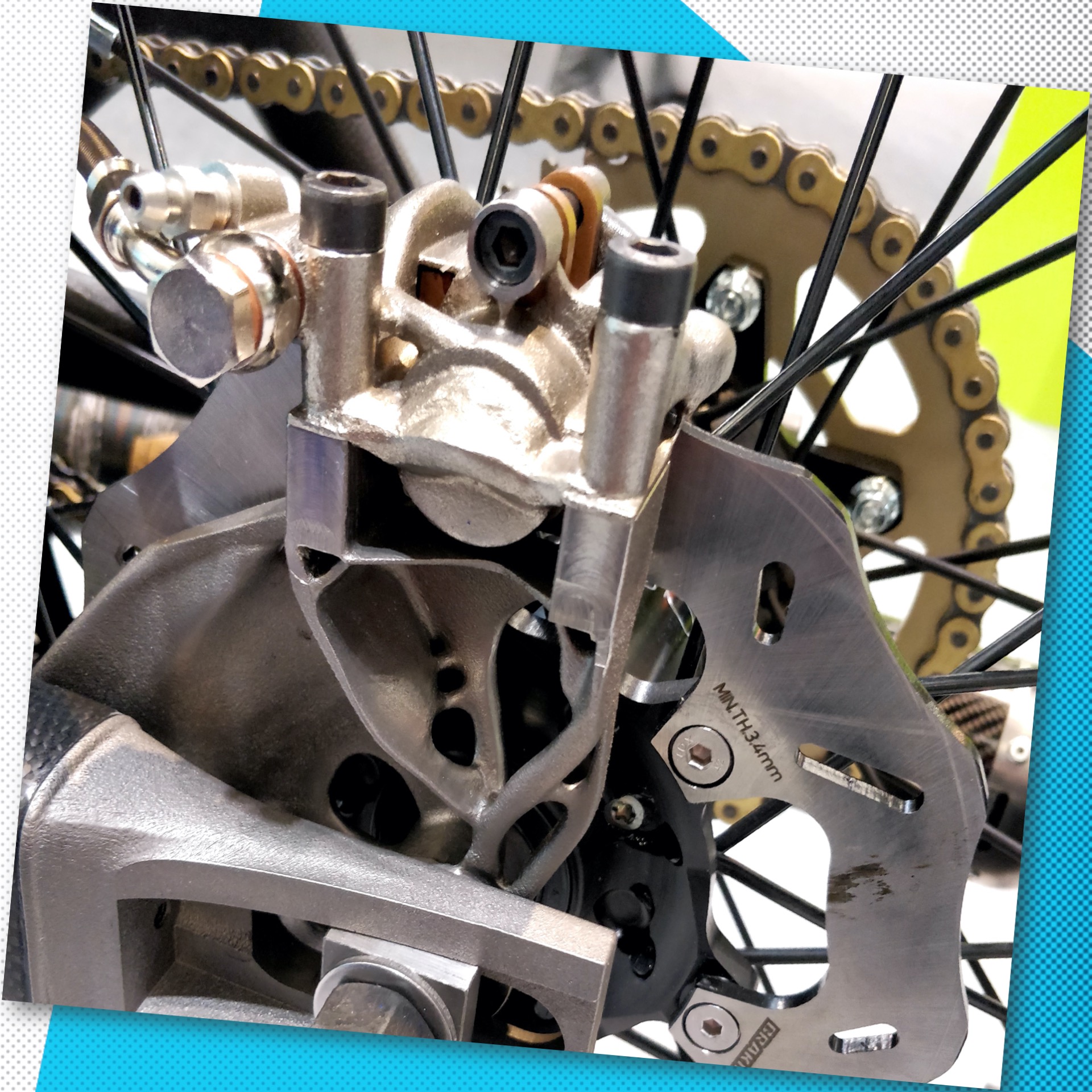

These are: Automotive industry, aerospace technology, tool and mould construction, special machine construction, automation technology, architecture, medical technology and prosthetics. Some of these examples can be seen in the picture slider of this article.

3D Printing in industry: From prototyping to toolmaking

With the help of various technologies (e.g. FDM, stereolithography, SLS…) 3D printing can meet almost all requirements. Depending on the complexity of the object, various materials (e.g. PLA plastics, metals, titanium, resins…) are used. In the meantime, 3D printing has found numerous areas of application in industry such as prototyping, single-part production, tool making, exhibits for trade fairs and much more.

With a growth forecast of about 30 %, a study certifies an immense volume for the 3D printing process across all industries. With developments in industry and research, it’s not surprising that this technology is on the cutting edge, as 3D printing offers many solutions to the challenges companies face.

3D Printing: The solution to many industrial challenges

Sooner or later the 3D printing process will become the standard in many areas of industrial production in the course of digitalisation and competitive pressure. Here you can see what benefits additive manufacturing already has today.

3D Printing in the area of Leoben and on Montanuniversität

3D Printing related statements of famous managers