Metallurgy student Lukas Neumayr was able to gain insights into the production of the future at Formnext 2019 in Frankfurt.

Formnext is the leading trade fair with over 800 exhibitors in the field of additive manufacturing and its entire upstream and downstream processes. The focus is on the area of design through to the production of prototypes and series models and on the efficient realisation of product ideas.

Diverse industrial sectors such as automotive, aerospace, mechanical engineering, medical technology, electrical engineering and many more use additive manufacturing, industrial 3D printing to discover innovative production technologies for themselves.

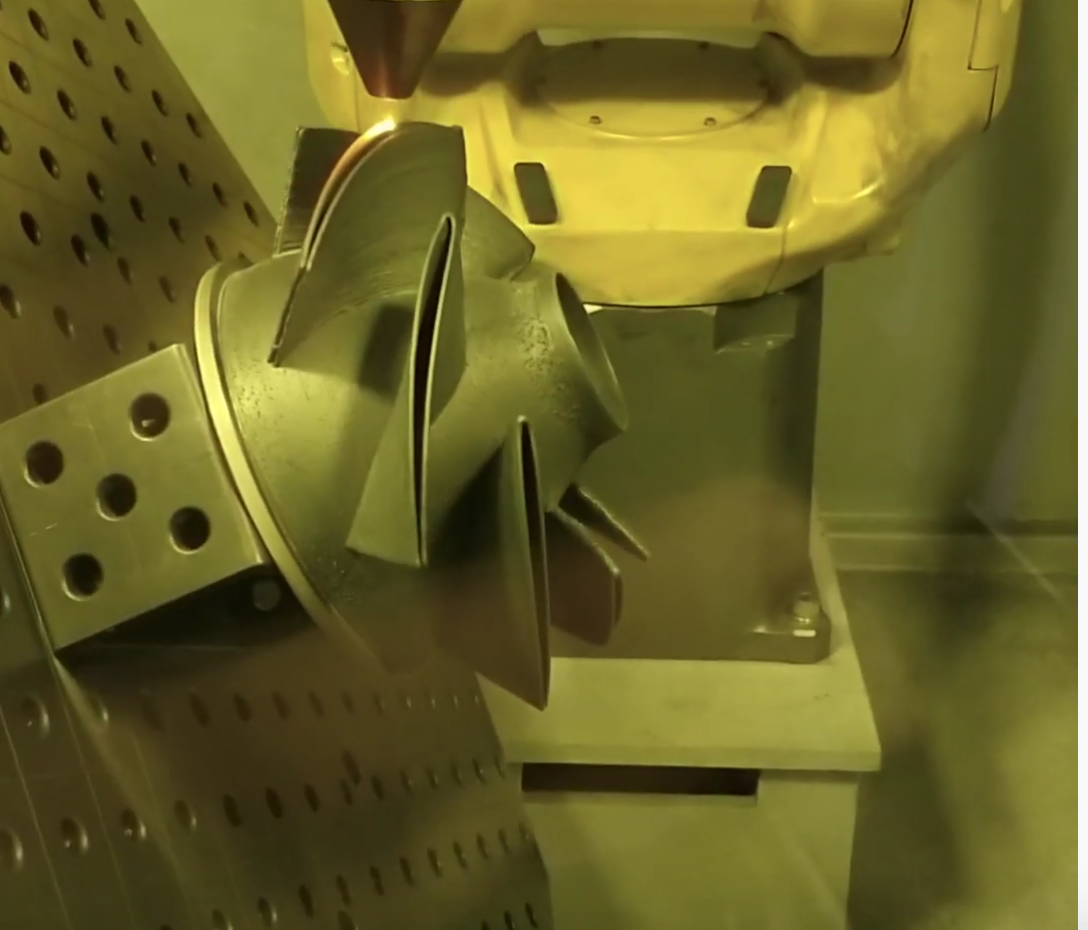

Video: “Laser Metal Deposition“, abbreviated LMD, sometimes also called “Direct Metal Deposition” (DMD) or “Direct Energy Deposition” (DED), is another way of additive production. Laser deposition welding is a generative manufacturing process for metal. A laser generates a melting pool on the component surface. Metal powder is automatically blown in through a nozzle. Welded layers, caterpillars, which result in extrusions on existing basic bodies or new components, are produced. The process is used in industries such as aerospace, energy technology, petrochemistry, the automotive industry, medical technology and other sectors.

Creating Metals – Creating Value